My process is tailored to the client, timeline, and product at hand. I aim to stay dynamic, adapting as the project evolves, with steps often overlapping or revisiting earlier stages.

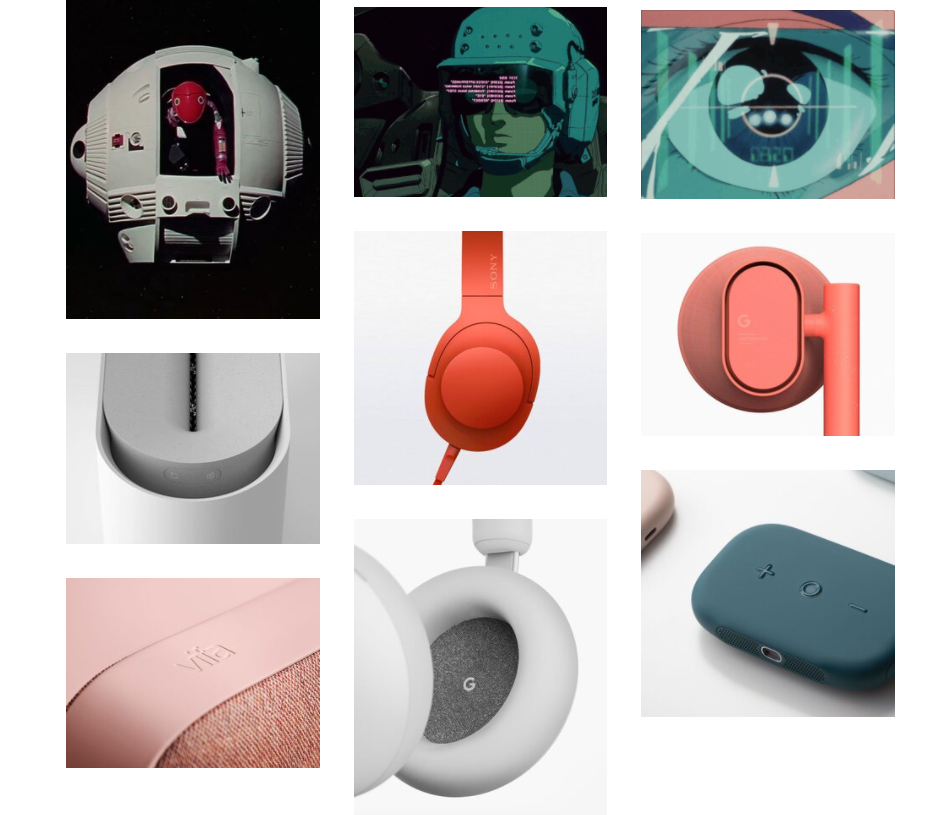

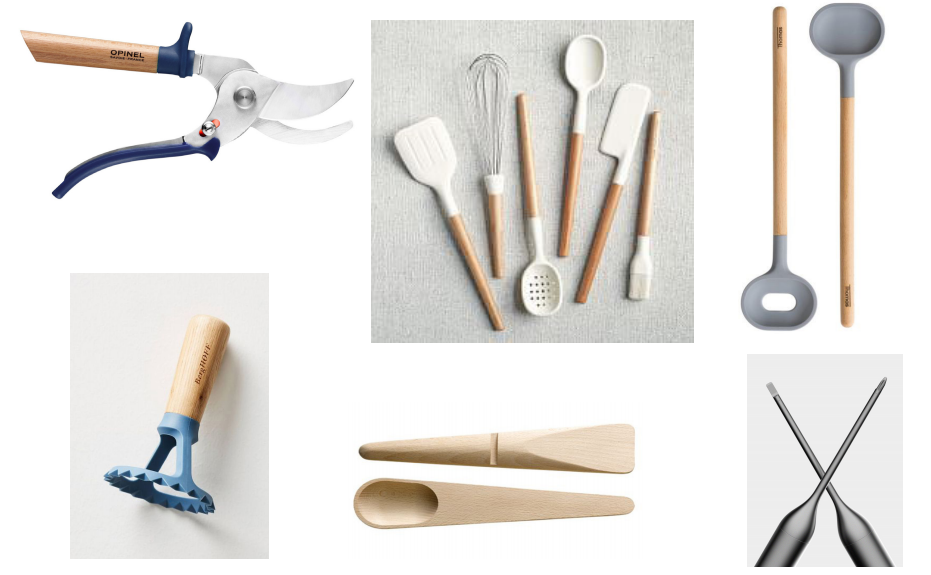

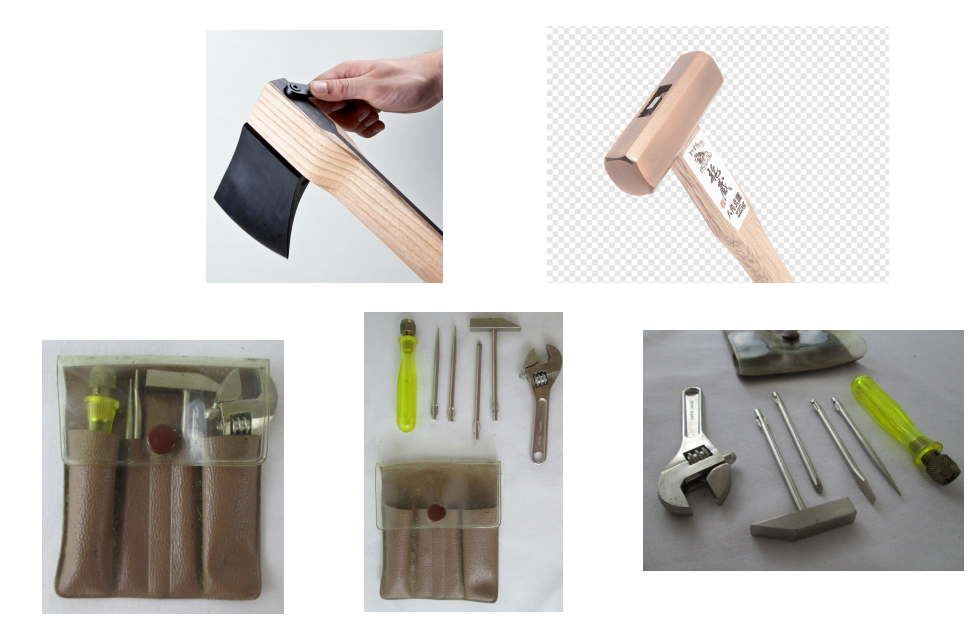

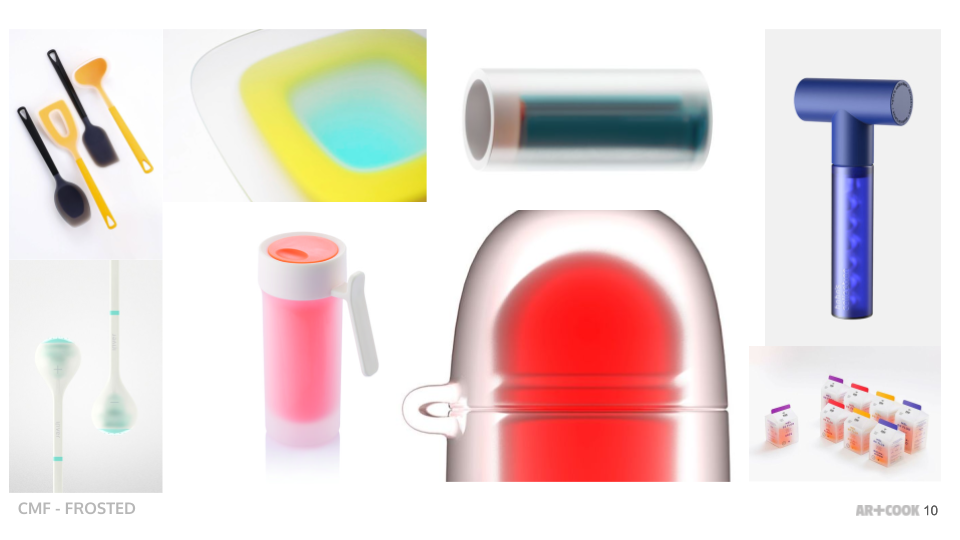

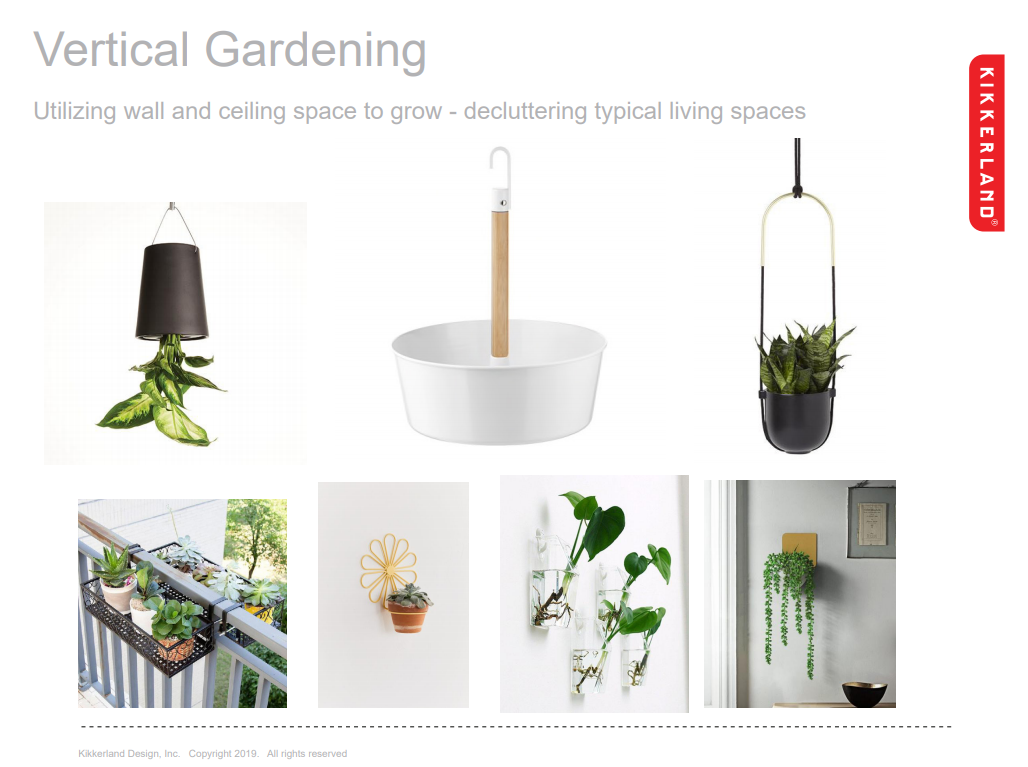

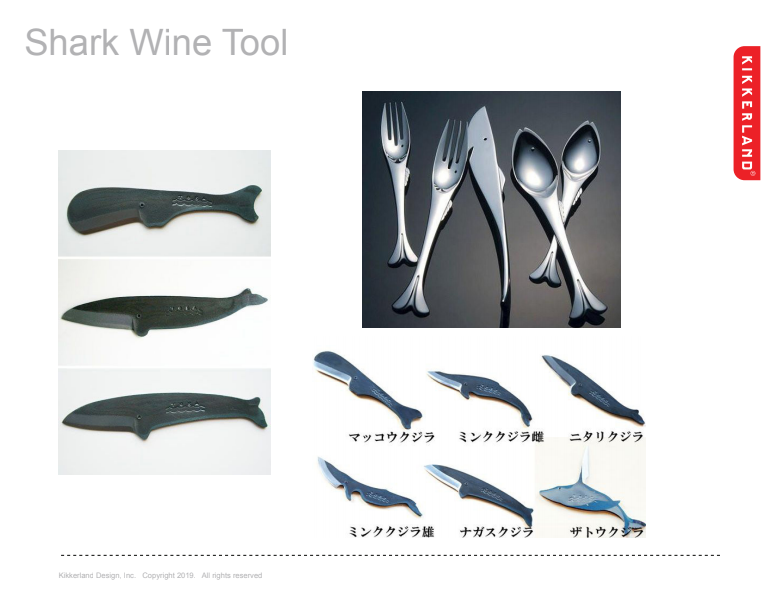

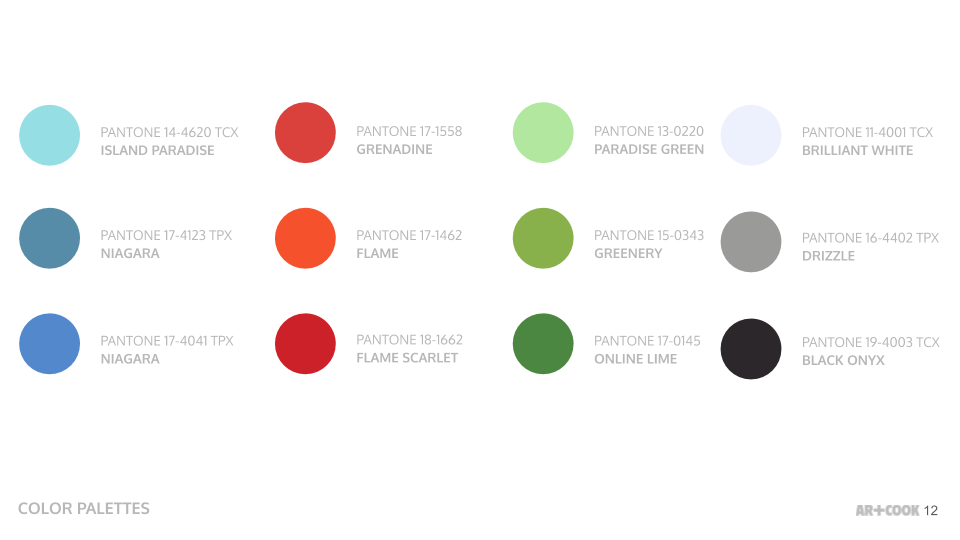

Research + Trend Boards

Researching the past, present and future of a product. Understanding the specific user or product. Trend and CMF boards. Reviewing the market landscape.

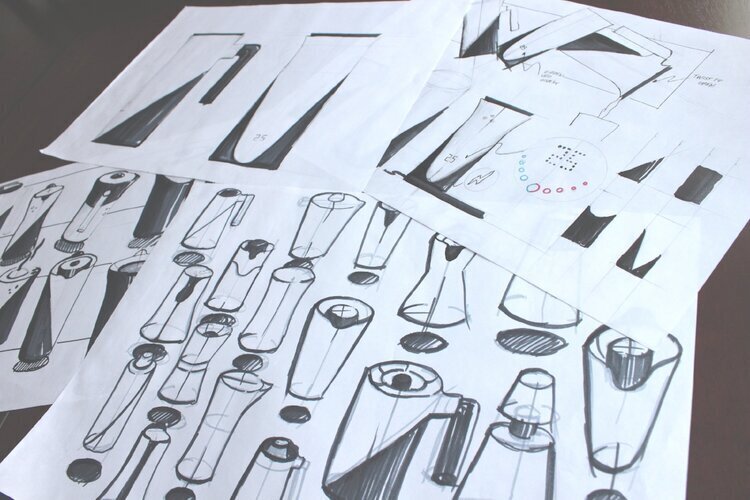

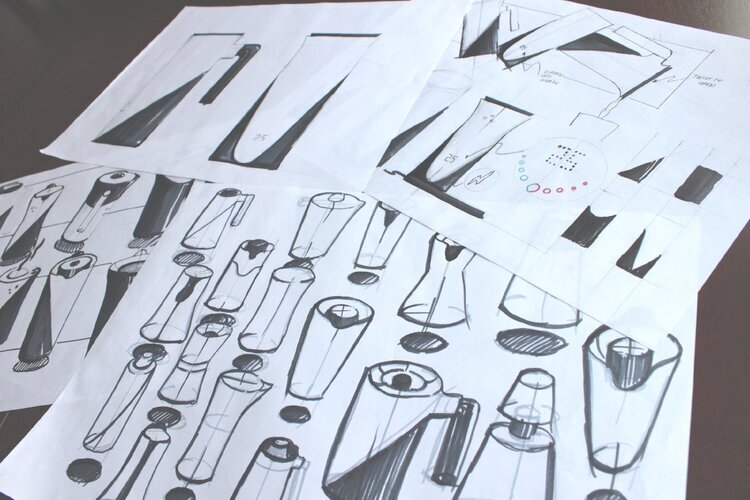

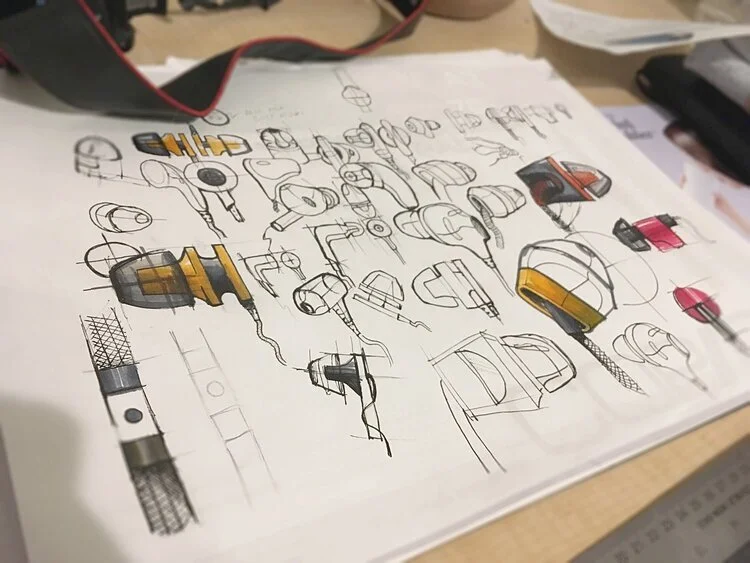

2. Sketching + Ideation

This stage is all about getting ideas to paper quickly, failing over and over again until you get that 1 out of 100 idea.

The sketches slowly evolve into a more resolved form where I try to understand scale, function, and details.

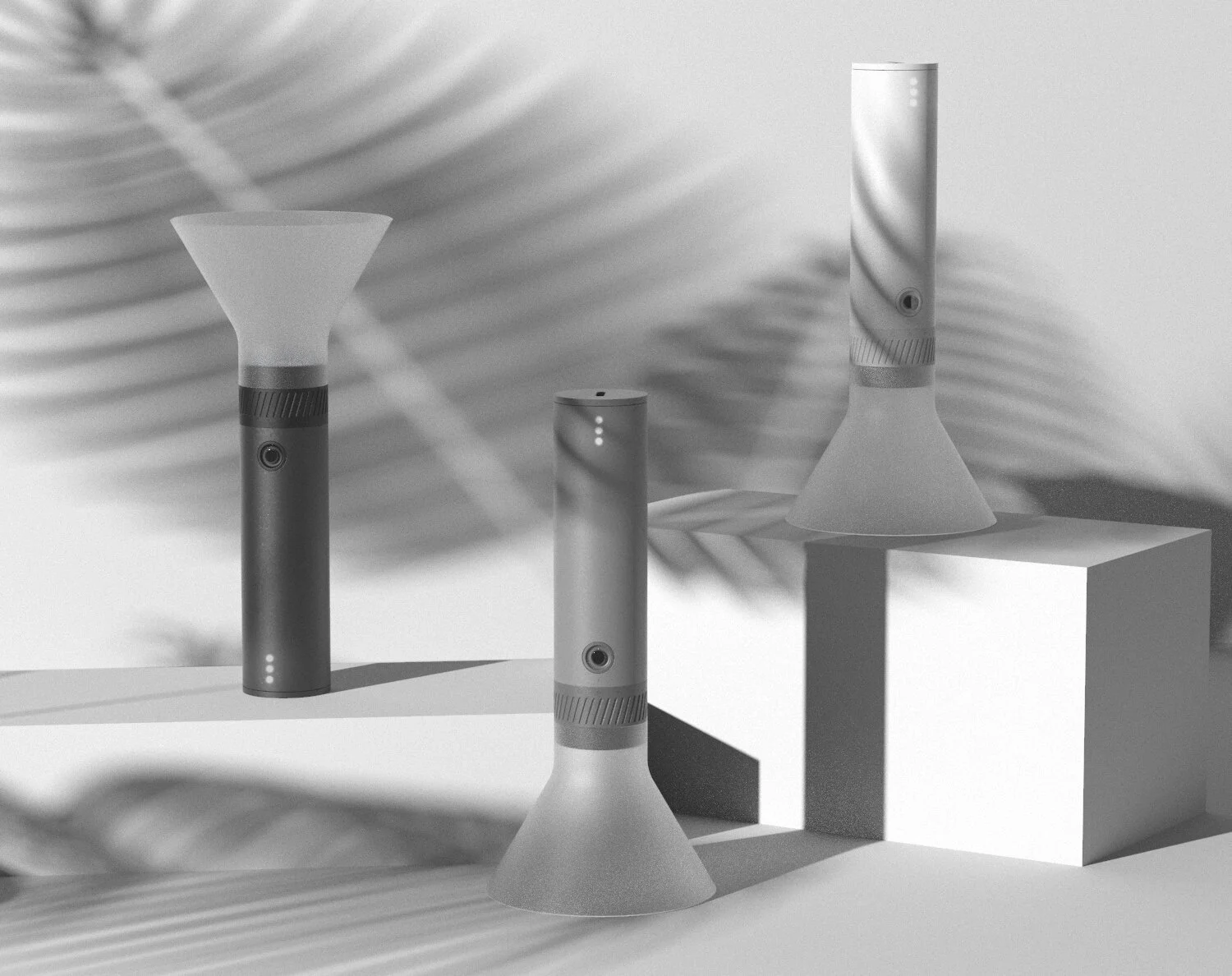

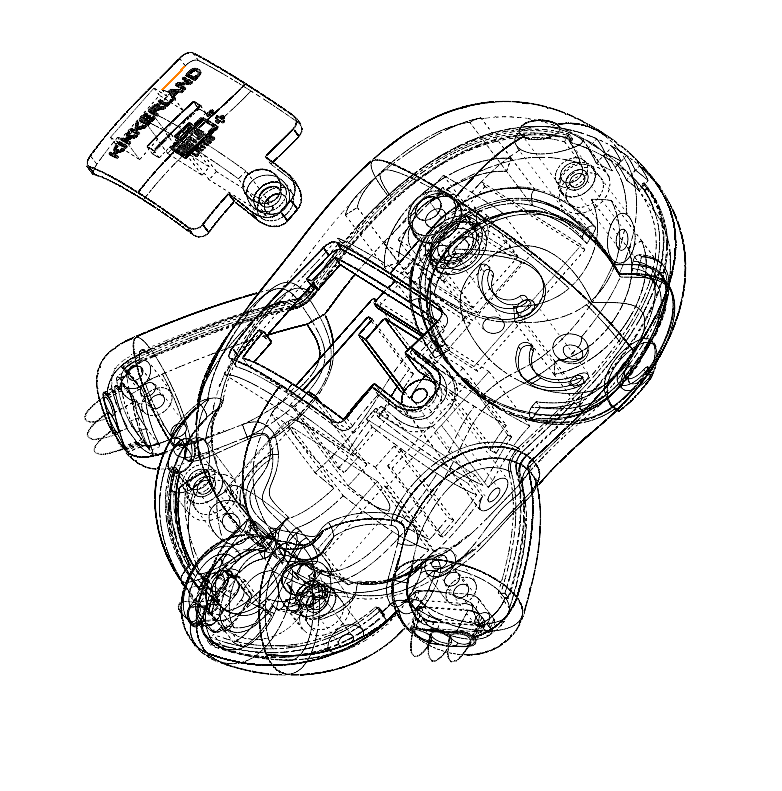

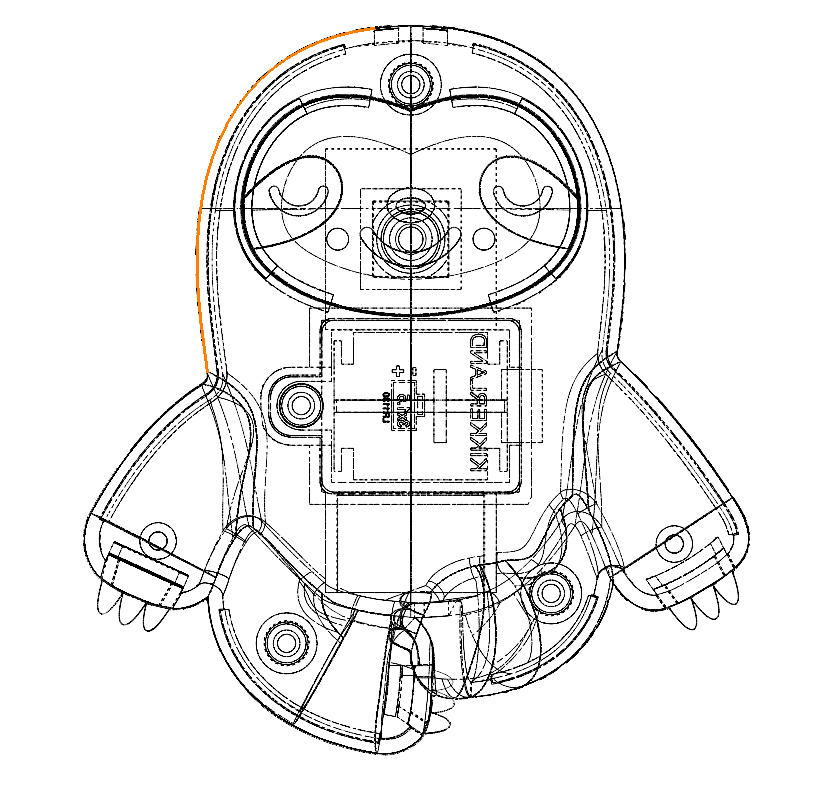

3. 3D Modeling + Rendering

At this stage the sketch is mostly finalized. Jumping into CAD allows myself to workout details and justify the scale of the object.

Most of the time, I also rapid prototype or circle back to sketching to solidify ideas further.

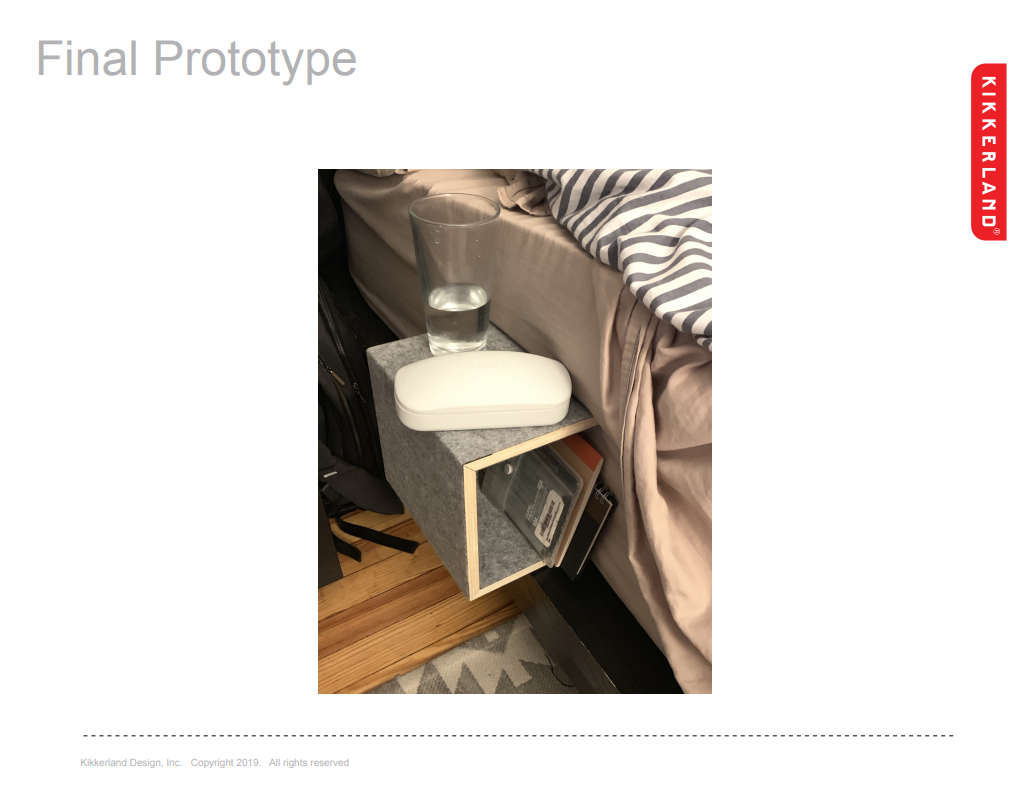

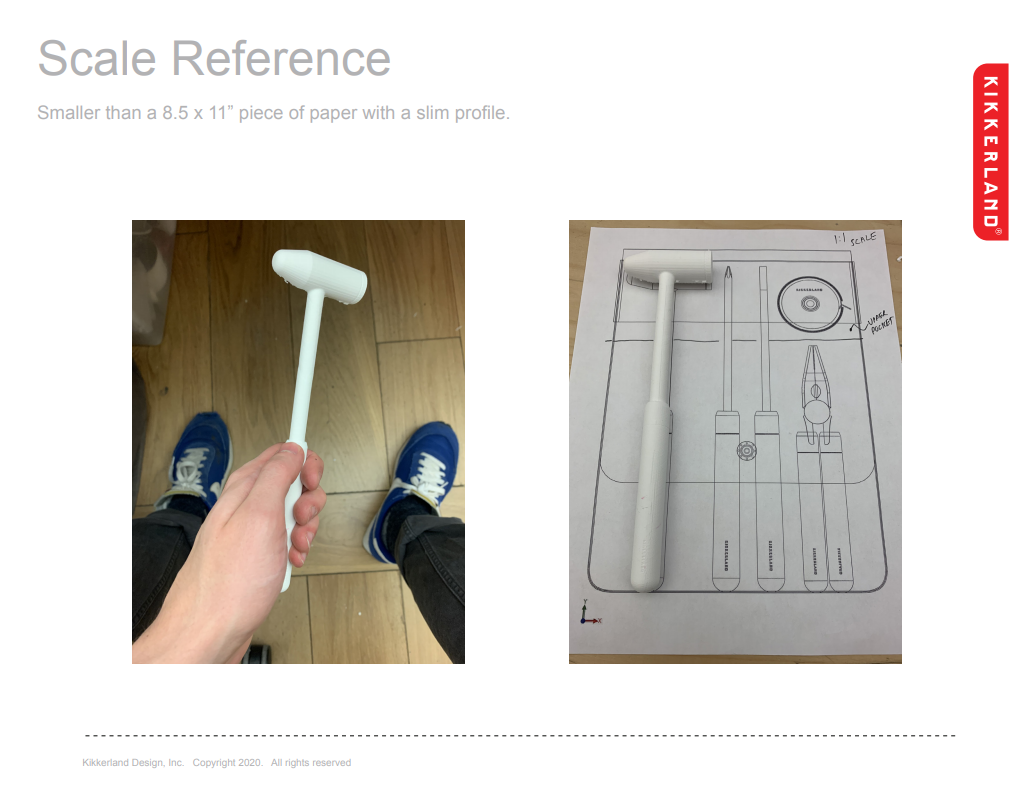

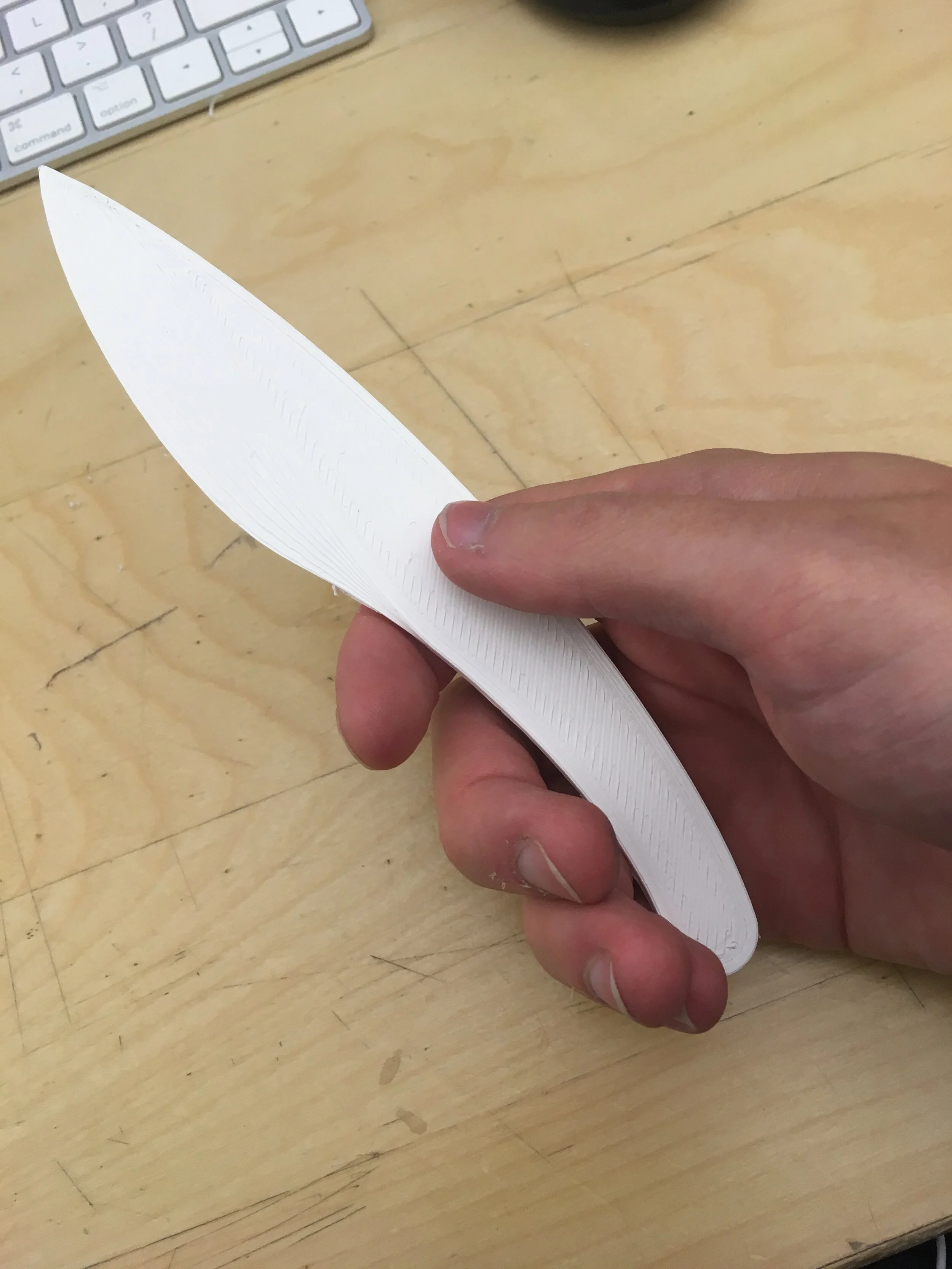

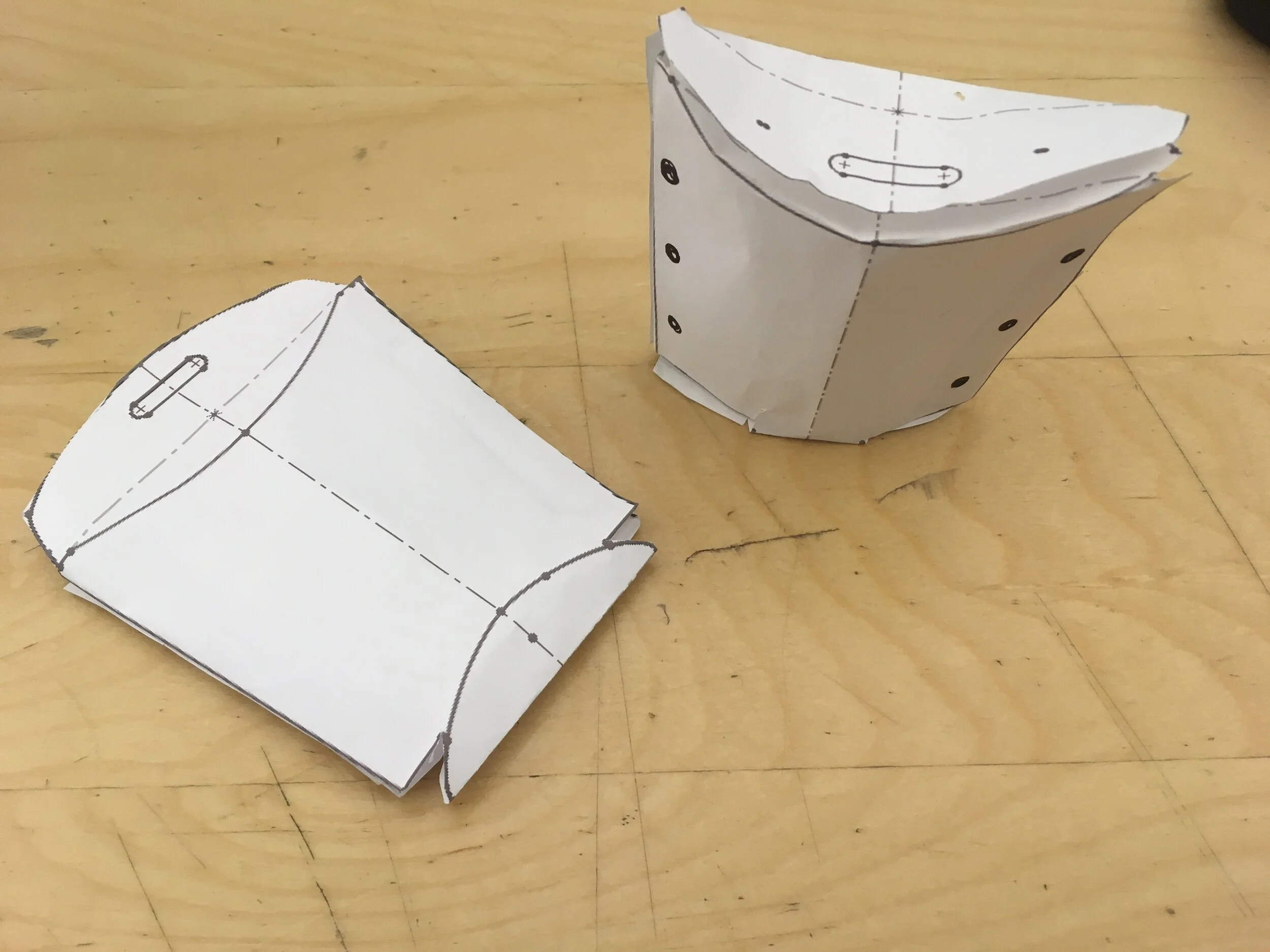

4. Rapid Prototyping, 3D Printing, User Testing

Taking a sketch or 3D model and making it an object you can hold in your hand to test. Foam models, 1:1 scale printouts, 3D prints, cardboard mockups, and wood/metal prototypes.

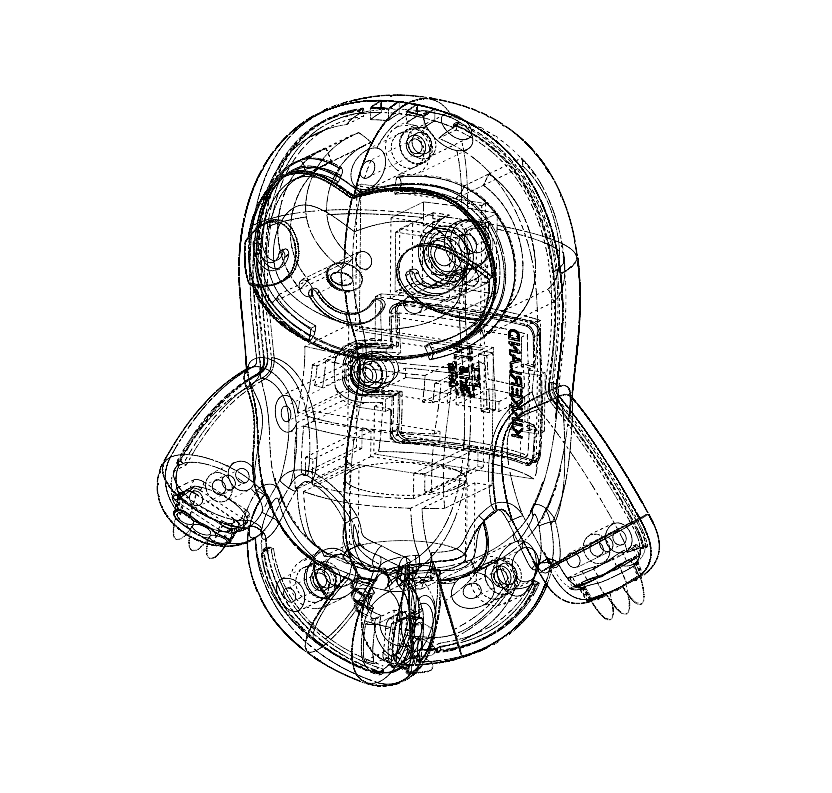

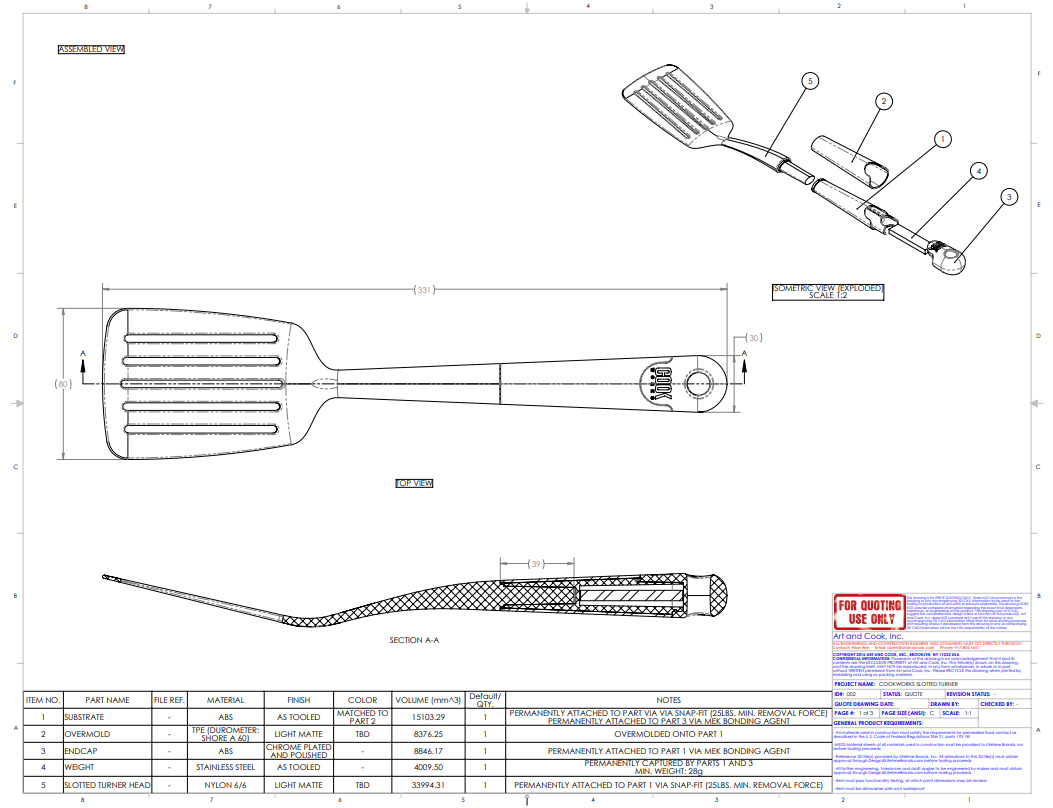

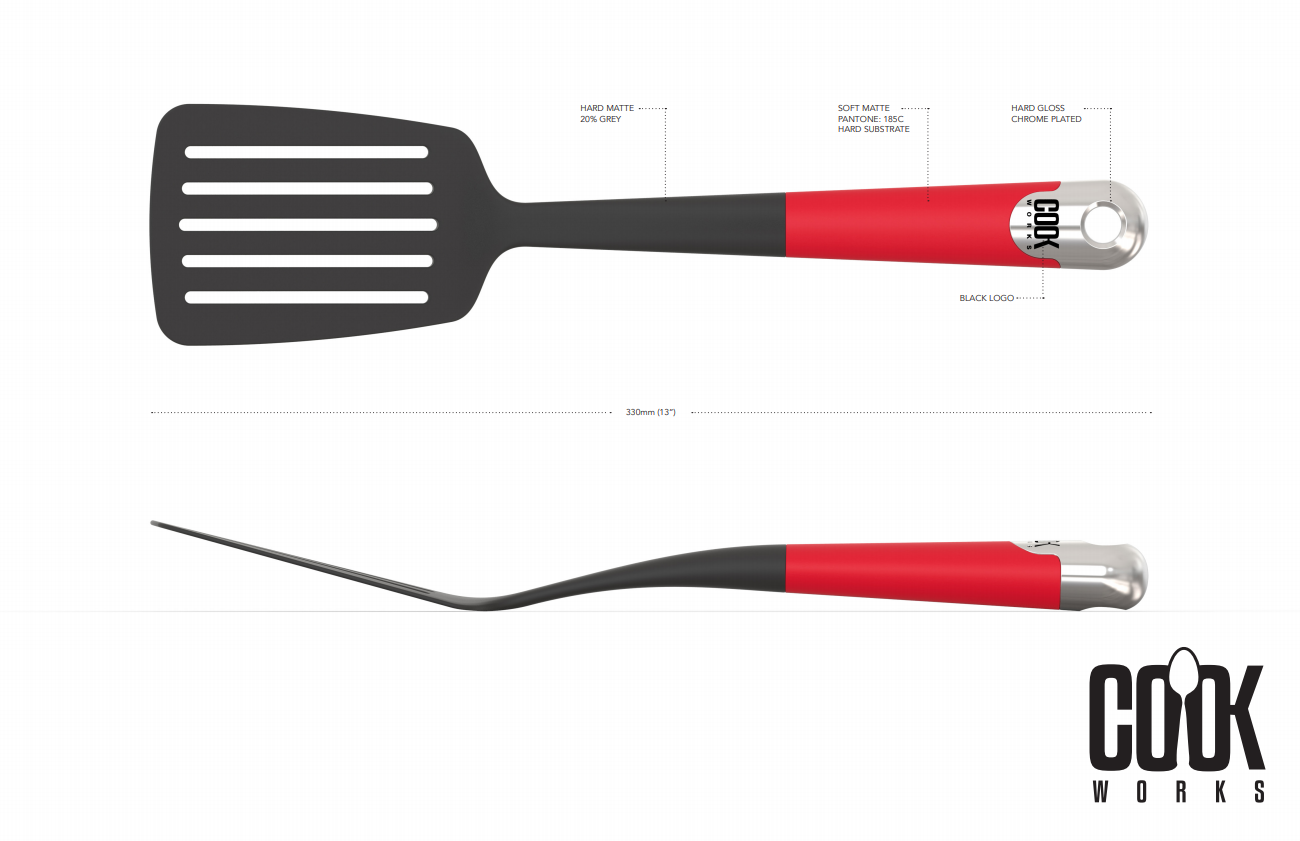

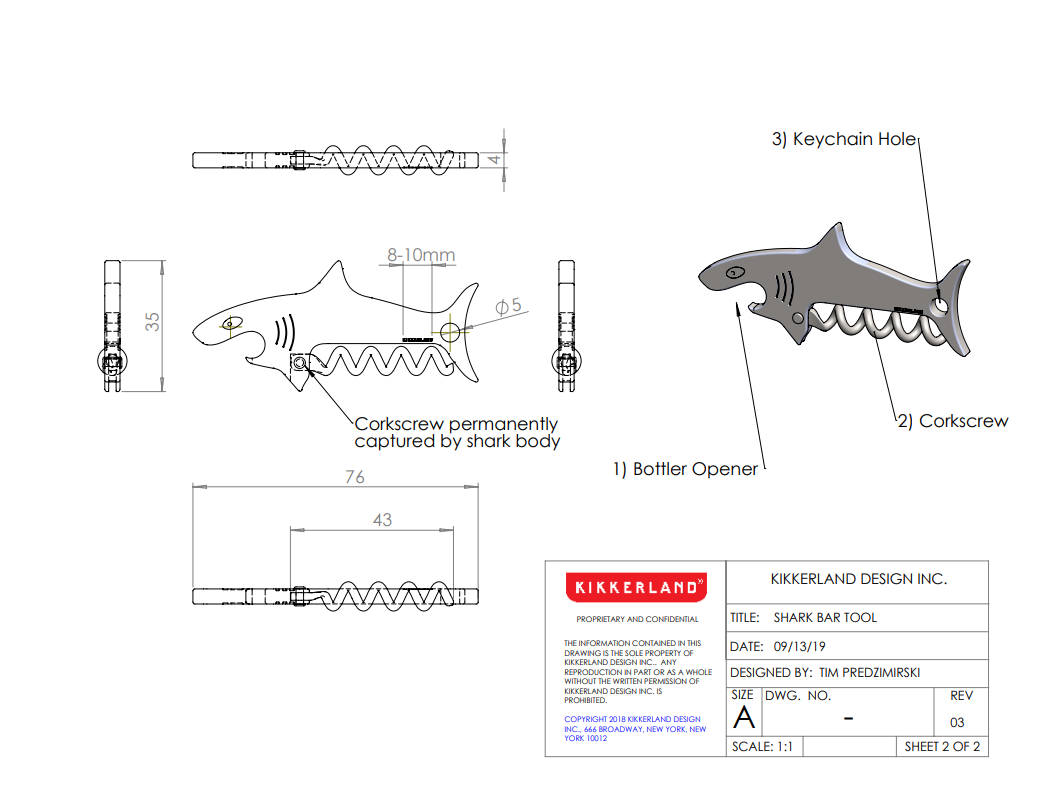

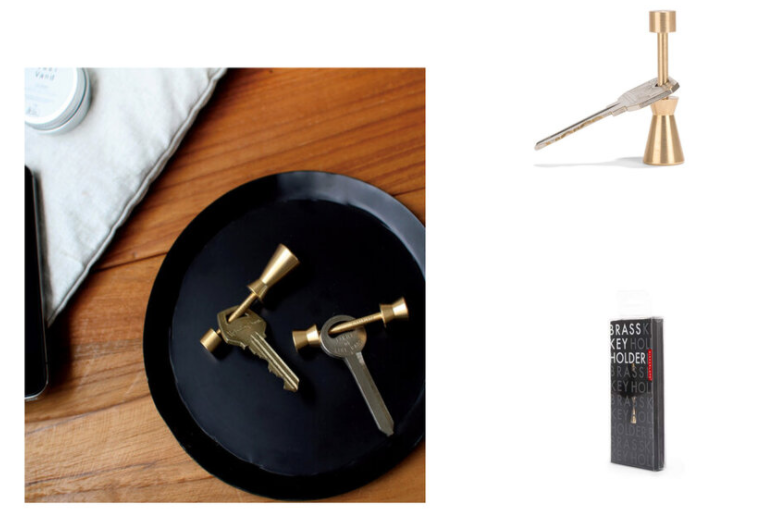

5. Drawings / CMF

Once the prototype is confirmed to be the desired functionality, scale, and design I jump into the drawing phase for quoting with a factory.

Here is where I decide on the final CMF (Color, material, finish) of an object and circle back to the 3D modeling stage to refine ideas and improve manufacturability.